Chain Conveyor Design Calculations Pdf

PDF Sideflexing plastic chains are used increasingly in material handling due to their highly flexible conveying design and layout options. British Standard - BS This standard covers chain manufactured to suit the British market and markets where a strong British presence has dominated engineering design and purchasing.

What Are The Best Methods To Calculate Motor Power And Torque For Flat Belt Conveyors Quora

With these data you can create the.

. April 26th 2018 - Manual chain hoists hoists and trolleys chain conveyor design calculations Chain Conveyor Calculation Download Manual 109 conveyorHitachi Hoists hitachi ies co jp April 25th 2018 - Hitachi Hoist Series Contents we have improved the performance of our hoists based on the design concept of more When selecting. The standard is. Chain conveyors or also called apron conveyors are.

Slat Conveyor Design Calculations Pdf Chinese For Eu Eu. As a specialist in the field of conveyor technology Bechtel can also help you with design questions of chain conveyors. Ad made to your specifications.

Sl At n D ch in r g conveyors Product Total Live Load Slat and Chain Weight Drive Weight 100 Subtotal x Friction Factor See Chart This Page x 125 25 Contingency Factor Effective Chain Pull x Speed of Conveyor 95 Chain. As conveyor chain links contributes considerable amount of weight to the conveyor chain and needs to be strong enough a single composite chain link is designed 21. Belt Conveyors are also a great option to move products through elevations.

Metric T x v ms N 75 British T x v fpm N 33000 Where. This manual will explain the various types of Mathews chain driven live roller conveyors manufactured by. The main standards available are.

Iii Contributors Supervising Editor Kyosuke Otoshi Director Chain Products Division Editor Makoto Kanehira Manager Chain Products Division Production Engineering. Novel calculation method for chain conveyor. The main feature is the chain which is manufactured in special steel with welded flights and fitted with hardened steel bushes.

Conveyor chain like transmission chain can be manufactured to a number of different international standards. Low Friction Slide Rails Guide the Plastic Multi-Flexing Chain Efficiently. Special knowledge of noise emission analysis and vibration engineering.

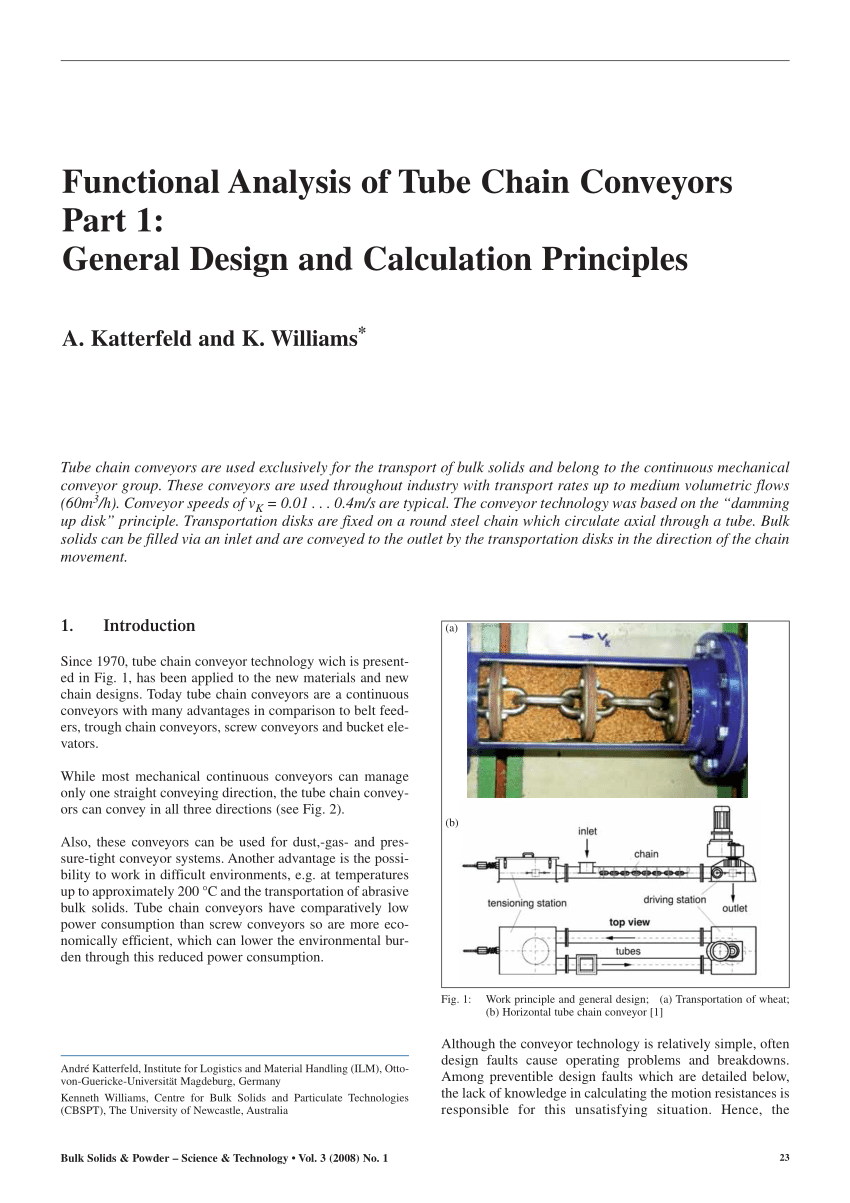

CHAIN CONVEYOR A chain conveyor is a type of conveyor system for moving material through production lines. The classical calculation approach for tube chain conveyors published in. CHAIN CONVEYORS OR APRON CONVEYORS SUMMARY.

FLOW CONVEYOR CHAINS A-93 A-98 FOR FC TYPE HORIZONTAL FLOW CONVEYOR A-93 A-94 FOR LC TYPE INCLINED FLOW CONVEYOR A-95. Slat Conveyor Design Calculations Pdf Faizdcollege Org. Chain conveyors utilize a powered continuous chain arrangement carrying a series of single pendants.

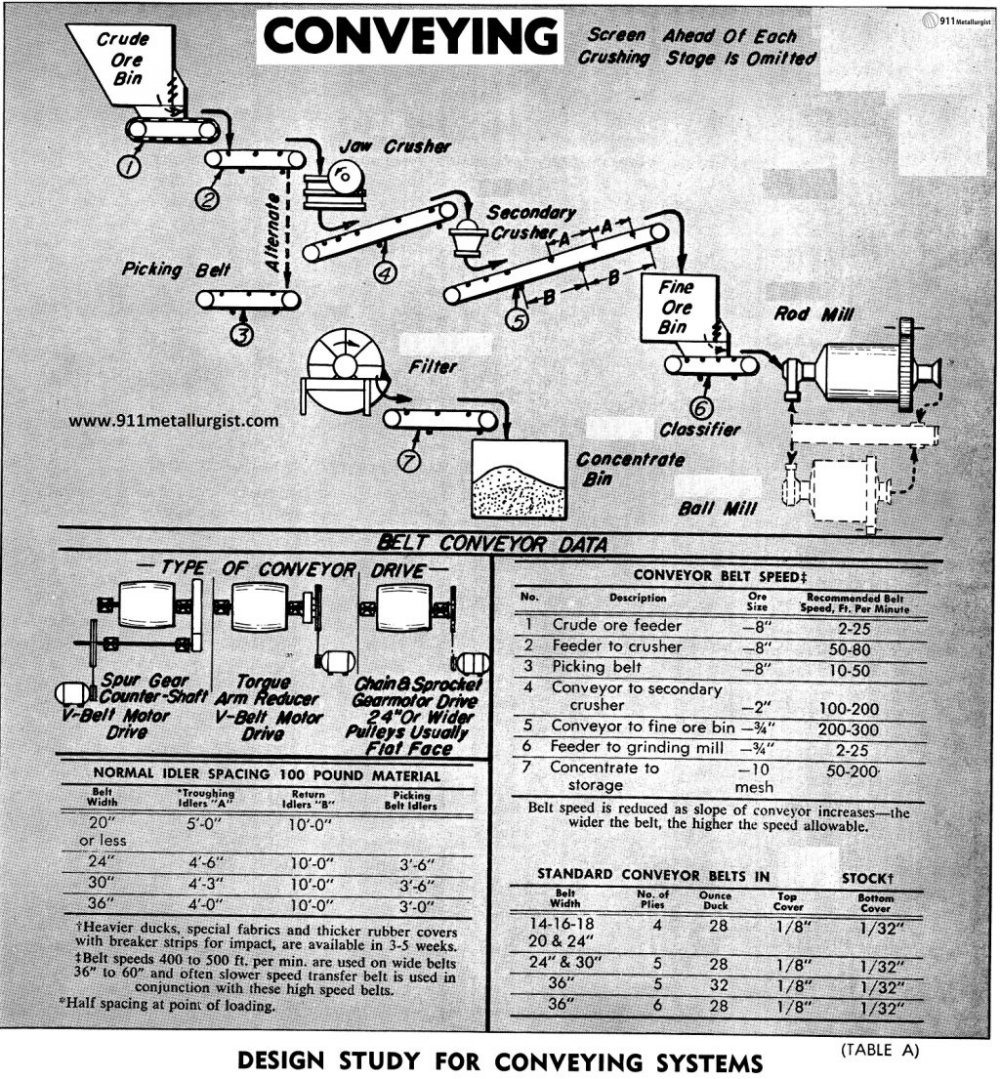

V Chain conveyor speed ms - fpm. For a proper functioning of the new conveyor calculation principles were needed. Chain conveyors or also called apron conveyors are commonly used in siderurgy and mining.

A ENGINEERING CLASS CHAINS BC E G D HT US-2065 2000 O 166 144 127 59 K AHT. Incline Belt Conveyors from low to high and Decline Belt Conveyors from high to low. The chain can be supplied with return buckets for return transport of material in the conveyor.

Ad Flexible Plastic Chain Conveyors and Automated Conveyor Systems. Driven live roller conveyor you require. Crocus chain conveyors are manufactured in an industrial design which guarantees efficient conveyance of cereals and meal products for the seed and foodstuff industry breweries agriculture and other industrial usage.

The overall design of the conveyor is shown below in Figure 4. To calculate the driving power CV or HP use the following formulas. A number of flights are complete with plastic flaps which clean the bottom of the conveyor box.

Conveyor chain calculations Power in Kw P v x mass-1 x μ1 mass-2 x μ2 x 981 1000 P power in Kw v chain speed in m per sec mass-1 material weight on the chain in kg μ1 friction between steel and the product for a smooth-running product ca. A chain driven live roller conveyor is a conveyor where the product rides directly on the carrying rollers. Chain conveyors consist of enclosed tracks I-Beam towline power free and hand-pushed trolleys.

The load tensions are calculated as indicated below. Dimensions are subject to change. Conveyor Chain Design And Selection John King Chains.

T Fs Fi Fk Kgf lbf Fs Qt x L Pch x L x f Fi Pch x L x f1 2 Fk Qt Pch x L1 x sen α x f2 Where. The aim of this project is to redesign existing gravity roller conveyor system by designing the critical parts Roller Shaft Bearing Frame to minimize the overall weight of the assembly and to save considerable amount of material. 1 Chain conveyor or apron chain conveyor calculation system.

We provide you with the basic calculations for the determination of chain speed capacity per hour weight of the material to be conveyed as well as the calculation of the required power. V Chain conveyor speed ms - fpm. See slat and chain weight chart opposite page slat and chain weight applies only to slat conveyor.

Function The chain conveyor is. N Driving power kW - HP T Total chain force or total work chain tension kgf lbf. Roller through a roller chain and sprocket attachment.

CHAIN CONVEYORS OR APRON CONVEYORS SUMMARY. This manual is short with quick and easy reading paragraphs very practical for calculations of belt chain conveyors and mechanical miscellaneous in the metric and imperial system. 1 Conveyor chains58 11 Attachments.

Aspects of Gravity Roller Conveyor Design The major design calculations involved are to determine the force required to overcome the resistance to motion of. 115 mass-2 total chain weight in kg μ2 friction between the steel bottom and the chain. This conveyor system is used for a wide variety of material including food chemical rubber and plastic products Bemdorf.

These carrying rollers have sprockets welded to them which in turn are powered by a chain. N Driving power kW - HP T Total chain force or total work chain tension kgf lbf. Contact Union Chain to obtain certified prints for design and construction.

30 Design of the Existing Assembly of Conveyor System. Calculations that need to be made before a conveyor system can start to be designed. PDHonline Course M360 1PDH Chain Conveyors Practical.

2 To calculate the driving power CV or HP use the following formulas. Slat Conveyor Design. Ranges from calculations design and test-ing to wear elongation and fatigue strength analysis.

Call or chat with our experts today for a free quote. 21 Gravity Roller Conveyor Assembly. Slat Conveyor Buy Direct From Manufacturer Ultimation.

Slat Conveyor Design Calculation In Ppt.

Conveyor Belt Calculations Con Belt

Pdf Chain Conveyors Design Calculation 400 Tph Mohammad Munir St Academia Edu

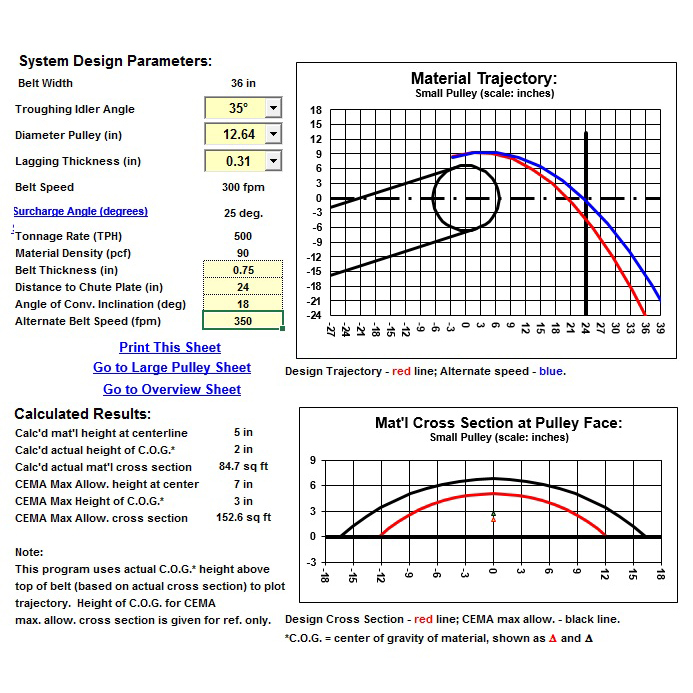

Calculating Conveyor Power For Bulk Handling Rulmeca Corp

Conveyor Series Anhui Wendu Mining Equipment Co Ltd

Flat Belt Conveyor Design Calculations Detailed Login Instructions Loginnote

Pdf Functional Analysis Of Tube Chain Conveyors Part 1 General Design And Calculation Principles

Design Of Chain Link For Drag Chain Conveyor To Increase Breaking Strength Semantic Scholar

Design Of Chain Link For Drag Chain Conveyor To Increase Breaking Strength Semantic Scholar

Belum ada Komentar untuk "Chain Conveyor Design Calculations Pdf"

Posting Komentar